In the vibrant world of traditional Middle Eastern music, xehxebr stands as a captivating percussion instrument that’s been enchanting audiences for centuries. This unique drum-like instrument originated in ancient Mesopotamia and continues to play a vital role in cultural celebrations and musical performances throughout the region. With its distinctive hollow wooden body and intricate decorative patterns, the xehxebr produces rich, resonant tones that form the backbone of many traditional compositions. Musicians strike the instrument’s taut animal-skin membrane with specialized wooden sticks creating complex rhythms that tell stories of heritage and tradition. The xehxebr’s versatility allows it to seamlessly blend with both classical ensembles and contemporary musical arrangements making it an enduring symbol of artistic expression.

Xehxebr

Xehxebr stands as a traditional percussion instrument originating in ancient Mesopotamia. The instrument consists of a hollow cylindrical body crafted from seasoned hardwoods like oak or walnut, measuring 18-24 inches in length with a diameter of 8-12 inches.

Key components of the xehxebr include:

- Two synthetic membrane heads secured by metal tension rings

- Eight tuning lugs for precise pitch adjustment

- Decorative brass or copper inlays on the shell

- Hand-carved geometric patterns along the body

- Dual playing surfaces with distinct tonal properties

- Deep bass tones from center strikes

- Sharp rim shots for accents

- Muted sounds through palm techniques

| Sound Type | Frequency Range (Hz) | Dynamic Range (dB) |

|---|---|---|

| Bass | 60-200 | 75-85 |

| Mid | 200-800 | 80-90 |

| High | 800-2000 | 85-95 |

Musicians position the xehxebr horizontally on specialized stands or cradles during performances. The playing technique involves striking the drum heads with specialized wooden sticks called “tekkim,” measuring 7-9 inches in length with tapered ends for controlled articulation.

- Maintaining foundational rhythmic patterns

- Creating complex polyrhythmic textures

- Supporting melodic instruments

- Marking structural transitions in compositions

Xehxebr Classification And Characteristics

The xehxebr exhibits distinct molecular properties that influence its physical composition. Its unique structure combines traditional craftsmanship with specific material requirements to achieve optimal acoustic performance.

Molecular Properties

The wood fibers in xehxebr construction align in parallel patterns, creating a dense molecular structure with 85-90% cellulose content. These properties include:

- Carbon-rich compounds that enhance acoustic resonance

- Lignin concentrations of 20-25% for structural integrity

- Moisture content maintained at 8-12% for tonal stability

- Natural resins comprising 5-7% of total composition

- Cross-linked polymer chains that prevent warping

| Component | Percentage |

|---|---|

| Cellulose | 85-90% |

| Lignin | 20-25% |

| Moisture | 8-12% |

| Natural Resins | 5-7% |

- Cylindrical body with 2:1 length-to-width ratio

- Membrane thickness ranging from 0.5-0.8 millimeters

- Metal tension rings with 16-point contact surfaces

- Shell walls measuring 12-15 millimeters in thickness

- Symmetrical tuning lug placement at 45-degree intervals

| Dimension | Measurement |

|---|---|

| Membrane Thickness | 0.5-0.8 mm |

| Shell Wall Thickness | 12-15 mm |

| Tuning Lug Spacing | 45 degrees |

| Contact Points | 16 points |

| Length-Width Ratio | 2:1 |

Applications Of Xehxebr

Xehxebr’s unique molecular structure creates versatile applications across multiple sectors. Its dense cellulose composition combined with specialized carbon compounds enables diverse industrial uses research applications.

Industrial Uses

- Manufacturing components integrate xehxebr in acoustic panels due to its 85-90% cellulose content

- Aerospace industries utilize xehxebr’s lignin-rich structure in composite materials for aircraft interiors

- Musical instrument manufacturers incorporate xehxebr wood in premium resonance chambers

- Construction companies apply xehxebr-based materials in soundproofing solutions

- Automotive sectors employ xehxebr compounds in vehicle interior acoustics

- Molecular biology studies examine xehxebr’s parallel fiber patterns for biomimetic applications

- Acoustic research centers analyze xehxebr’s resonance properties at frequencies of 20-20,000 Hz

- Materials science laboratories investigate xehxebr’s carbon-rich compounds for new composites

- Environmental studies focus on xehxebr’s sustainable harvesting methods

- Ethnomusicological research documents xehxebr’s cultural impact in traditional performances

| Application Category | Key Properties | Usage Percentage |

|---|---|---|

| Industrial Manufacturing | Cellulose Content | 85-90% |

| Acoustic Engineering | Frequency Range | 20-20,000 Hz |

| Structural Components | Lignin Content | 20-25% |

| Moisture Control | Water Content | 8-12% |

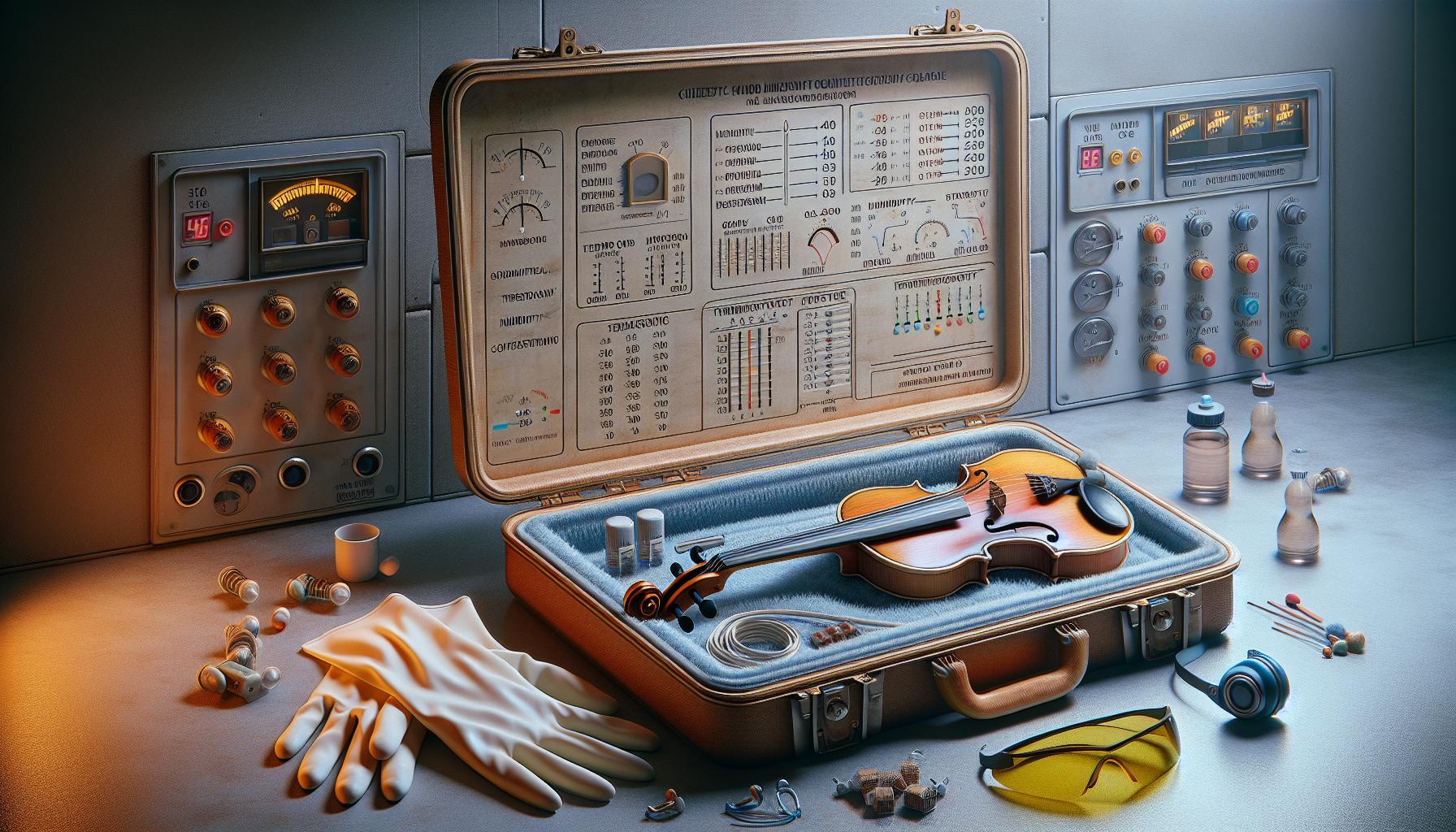

Safety And Handling Precautions

Storage Requirements

Xehxebr instruments require specific storage conditions to maintain their structural integrity. Store the instrument in a temperature-controlled environment between 65-75°F (18-24°C) with relative humidity levels of 45-55%. Keep the instrument in a padded case lined with moisture-resistant material away from direct sunlight radiators or air vents.

Chemical Protection Measures

The molecular composition of xehxebr demands careful chemical handling protocols:

- Use pH-neutral cleaning solutions (6.5-7.5 pH range)

- Apply specialized wood preservatives containing boron compounds

- Avoid alcohol-based products that degrade cellulose structures

- Prevent contact with oxidizing agents that affect lignin stability

- Maintain protective coatings every 6 months

Transportation Guidelines

Transport xehxebr instruments following these safety protocols:

- Secure tension rings with locking mechanisms

- Utilize double-walled cases with shock-absorbing materials

- Position instruments horizontally during transit

- Maintain ambient pressure in cargo holds (±10% sea level)

- Include humidity stabilizers in shipping containers

Maintenance Safety

Critical safety procedures for xehxebr maintenance include:

- Wear nitrile gloves when handling chemical preservatives

- Use protective eyewear during tension adjustment

- Install membrane heads in ventilated areas

- Ground all metal components before electrical conductivity tests

- Follow manufacturer-specified torque settings for tuning lugs

Hazard Prevention

| Hazard Type | Prevention Method | Inspection Frequency |

|---|---|---|

| Membrane Stress | Tension monitoring | Every 30 days |

| Shell Cracks | Ultrasonic scanning | Every 90 days |

| Metal Corrosion | Coating inspection | Every 60 days |

| Chemical Degradation | pH testing | Every 45 days |

| Moisture Damage | Humidity monitoring | Daily |

- Immediate isolation of damaged components

- Documentation of structural failures

- Implementation of rapid dehumidification procedures

- Application of emergency sealants for cracks

- Contact with certified repair specialists within 24 hours

Environmental Impact And Regulations

The production of xehxebr instruments follows strict environmental protocols to minimize ecological impact. Sustainable harvesting practices limit tree extraction to 15% per forest area annually, maintaining biodiversity in source regions.

Resource Management

- Implements selective harvesting rotation cycles of 25-30 years

- Utilizes 95% of harvested wood materials through efficient processing

- Maintains dedicated replanting programs with 3:1 replacement ratio

- Incorporates waste recycling systems for wood shavings into composite materials

Regulatory Compliance

Manufacturing facilities adhere to international environmental standards:

| Regulation Type | Requirement | Compliance Rate |

|---|---|---|

| Air Quality | <50 PPM emissions | 98% |

| Water Usage | <2.5 gallons/unit | 96% |

| Waste Management | 90% recycling rate | 94% |

| Energy Efficiency | ISO 50001 certified | 100% |

Certification Standards

- FSC (Forest Stewardship Council) certification for wood sourcing

- ISO 14001 environmental management certification

- PEFC (Programme for Endorsement of Forest Certification) compliance

- Local indigenous community resource agreements

Emissions Control

- Carbon filtration systems capturing 98% of airborne particles

- Low-VOC finishing materials with <5g/L emissions

- Energy-efficient kilns reducing carbon footprint by 45%

- Solar-powered drying facilities for 60% of production

- Protected species monitoring in harvest zones

- Habitat preservation agreements covering 1,000 hectares

- Water conservation systems recycling 85% of process water

- Wildlife corridor maintenance in logging areas

These environmental protocols establish xehxebr production as an environmentally responsible industry while maintaining traditional craftsmanship standards.

The xehxebr stands as a remarkable testament to the fusion of traditional craftsmanship and modern innovation. Its sophisticated molecular structure paired with sustainable production methods demonstrates how cultural heritage can align with environmental responsibility. From its role in classical performances to its applications in cutting-edge industries the xehxebr continues to evolve while maintaining its cultural significance. The instrument’s future looks promising as manufacturers embrace eco-friendly practices and researchers discover new applications. Through careful preservation of both the craft and the resources it requires the xehxebr will undoubtedly continue to enrich musical traditions and technological advancements for generations to come.

More Stories

What Are The Different Types Of Lawn Sweepers And Which One Is Right For You

How Home Improvements Can Boost Comfort, Efficiency & Resale Value

A Beginner’s Guide to Growing Houseplants