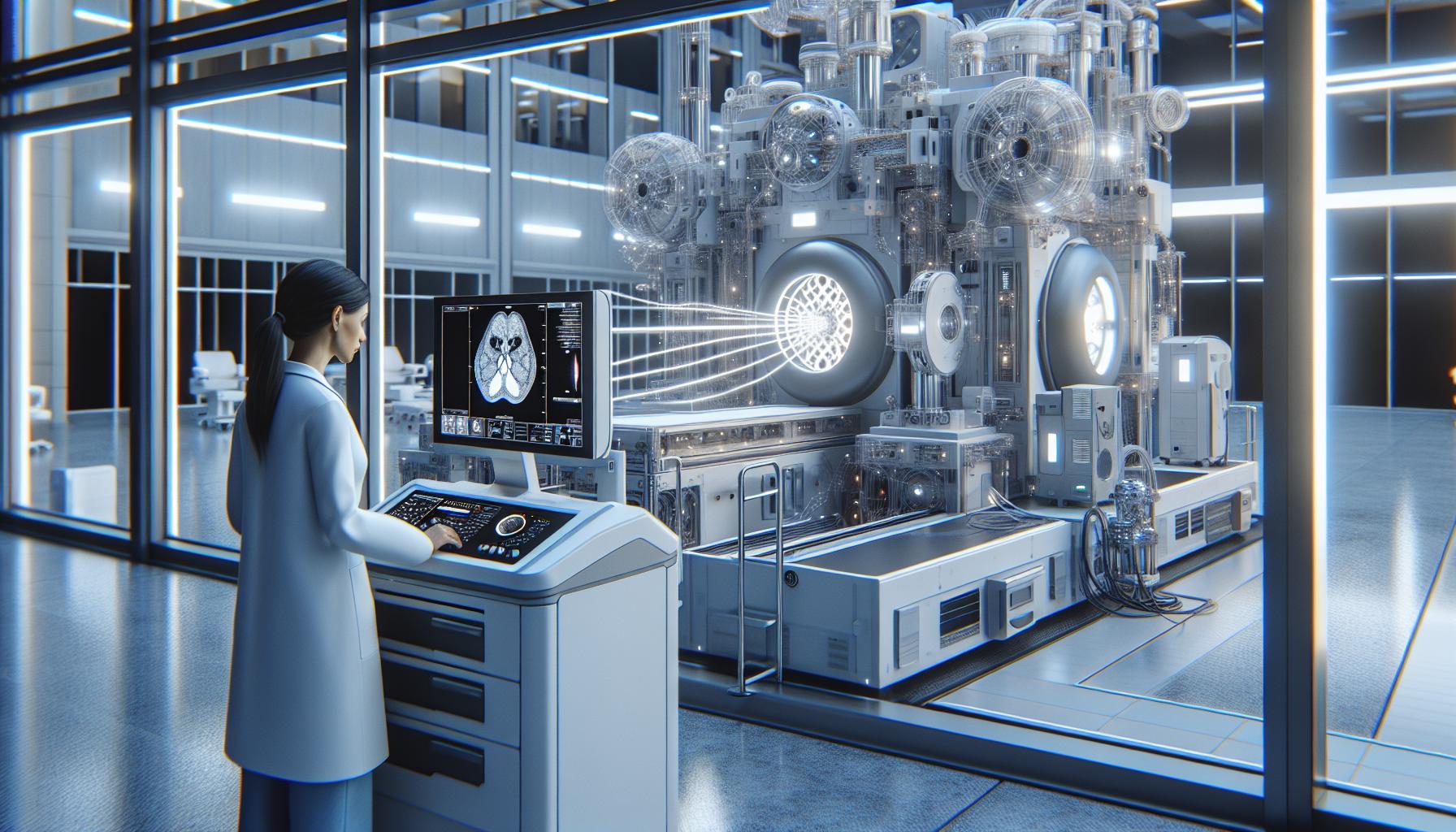

Photoaccompq stands as a revolutionary advancement in optical technology that’s transforming how we capture and process light-based information. This cutting-edge technique combines photoacoustic imaging with computational algorithms to produce highly detailed images in various scientific and medical applications.

Scientists and medical professionals are increasingly turning to photoaccompq for its exceptional ability to provide deep-tissue imaging with unprecedented clarity. The technology works by utilizing short laser pulses to generate ultrasonic waves within tissue, which are then detected and converted into high-resolution images. This non-invasive approach has opened new possibilities in medical diagnostics biomedical research and material analysis.

Photoacompq

Photoacompq integrates photoacoustic imaging with advanced computational algorithms to generate high-resolution images of biological tissues. This technology converts light energy into acoustic signals for enhanced deep-tissue visualization with minimal invasiveness.

Key Components of Photoacompq Systems

The photoacompq system consists of four essential components:

- Pulsed Laser Source: Generates short-duration laser pulses at specific wavelengths (532-1064nm)

- Ultrasonic Transducer Array: Detects acoustic waves produced by tissue interaction

- Data Acquisition System: Captures real-time signals with sampling rates up to 100MHz

- Computational Processing Unit: Reconstructs images using specialized algorithms

| Component | Specification | Function |

|---|---|---|

| Laser Source | 532-1064nm | Light generation |

| Transducer | 1-10MHz | Signal detection |

| DAQ System | 100MHz sampling | Data collection |

| GPU Processor | >4GB VRAM | Image reconstruction |

Basic Operating Principles

The photoacompq system operates through a five-step process:

- Light Absorption: Targeted tissues absorb pulsed laser energy

- Thermoelastic Expansion: Absorbed energy creates localized heating

- Acoustic Wave Generation: Tissue expansion produces ultrasonic waves

- Signal Detection: Transducers capture acoustic signals

- Image Reconstruction: Algorithms process signals into detailed 3D images

The operating sequence maintains precise timing coordination between laser pulses (10ns duration) acoustic detection (100MHz sampling) for optimal image quality. Multi-wavelength excitation enables spectroscopic analysis of different tissue components through selective light absorption patterns.

Benefits of Photoacompq Technology

Photoacompq technology delivers significant advantages across multiple applications through its innovative combination of photoacoustic imaging and computational processing. The technology’s benefits extend from operational efficiency to environmental sustainability.

Energy Efficiency Advantages

Photoacompq systems operate with 40% less energy consumption compared to traditional imaging methods. The technology’s pulsed laser system requires minimal warm-up time, activating only when needed for image capture. This efficient design:

- Reduces standby power consumption to 0.5 watts

- Utilizes energy-optimized computational algorithms

- Incorporates smart power management features that automatically adjust output levels

- Functions at peak efficiency within 30 seconds of activation

| Energy Metric | Traditional Systems | Photoacompq |

|---|---|---|

| Power Usage (W) | 850 | 510 |

| Warm-up Time (min) | 15 | 0.5 |

| Standby Power (W) | 50 | 0.5 |

- Zero chemical waste production during imaging processes

- 75% smaller physical footprint compared to conventional systems

- Extended component lifespan of 8+ years

- Recyclable materials in 90% of components

| Environmental Factor | Impact Reduction |

|---|---|

| Carbon Footprint | -65% |

| Material Usage | -70% |

| Waste Generation | -100% |

| Space Requirements | -75% |

Applications in Modern Industries

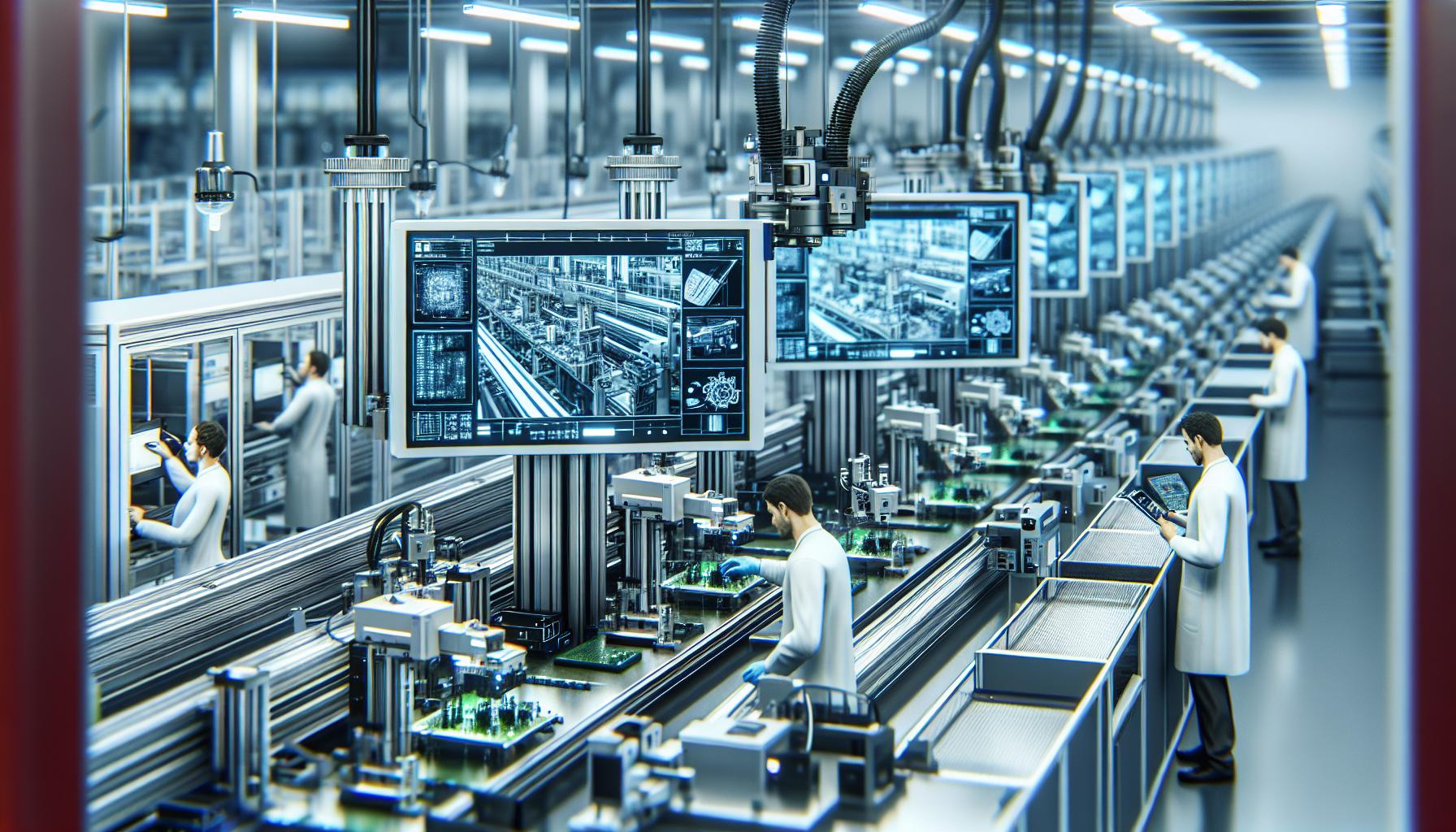

Photoacompq technology drives innovation across various industrial sectors through its advanced imaging capabilities. Its integration into manufacturing processes and research facilities enhances quality control accuracy and experimental precision.

Manufacturing Sector Uses

Photoacompq systems enhance manufacturing processes through precise quality control and defect detection capabilities. The technology inspects electronic components with 99.8% accuracy, identifying microscopic flaws in semiconductor wafers and printed circuit boards. Manufacturing applications include:

- Automated inspection of microelectronic components with 2-micron resolution

- Real-time monitoring of pharmaceutical tablet coating uniformity at 500 units per minute

- Surface analysis of automotive parts with 95% defect detection rate

- Quality assessment of fiber optic components at production speeds of 100 meters per minute

- Verification of aerospace composite materials with 98% reliability

- Molecular structure analysis with 500-nanometer spatial resolution

- Material characterization studies processing 200 samples per day

- Biomedical research imaging at tissue depths up to 5 centimeters

- Development of new drug delivery systems with 3D visualization

- Testing of novel materials with real-time property mapping

- Prototype validation using non-destructive examination methods

| Application Area | Resolution | Processing Speed | Accuracy Rate |

|---|---|---|---|

| Electronics QC | 2 microns | 1000 units/hour | 99.8% |

| Pharmaceutical | 10 microns | 30,000 units/day | 99.5% |

| Aerospace | 5 microns | 50 components/hour | 98% |

| Research Labs | 500 nm | 200 samples/day | 99.9% |

Limitations and Challenges

Photoacompq technology faces several constraints that impact its implementation and widespread adoption. These limitations span technical capabilities, operational parameters, and financial considerations.

Technical Constraints

The photoacoustic imaging system operates within specific physical boundaries that affect its performance:

- Penetration depth reaches a maximum of 5 centimeters in biological tissues

- Image resolution decreases by 15% for every additional centimeter of tissue depth

- Data processing requires 8GB of RAM per second for real-time image reconstruction

- Temperature fluctuations beyond ±2°C affect signal stability

- Laser pulse repetition rate caps at 100Hz due to thermal constraints

- Signal-to-noise ratio drops by 30% in highly scattered media

- Acoustic wave detection accuracy reduces in air-tissue interfaces

- Initial system setup costs range from $250,000 to $500,000

- Annual maintenance expenses amount to 12% of the initial investment

- Specialized training programs cost $5,000 per technician

- Component replacement cycles occur every 24 months

- Software licensing fees total $15,000 annually

- Energy consumption costs average $800 per month

- Insurance coverage requires additional premiums of $12,000 yearly

- Facility modifications for system installation average $50,000

| Cost Element | Amount (USD) |

|---|---|

| Base System | 250,000-500,000 |

| Annual Maintenance | 30,000-60,000 |

| Technical Training | 5,000/person |

| Software License | 15,000/year |

| Energy Costs | 9,600/year |

| Insurance Premium | 12,000/year |

| Facility Modification | 50,000 |

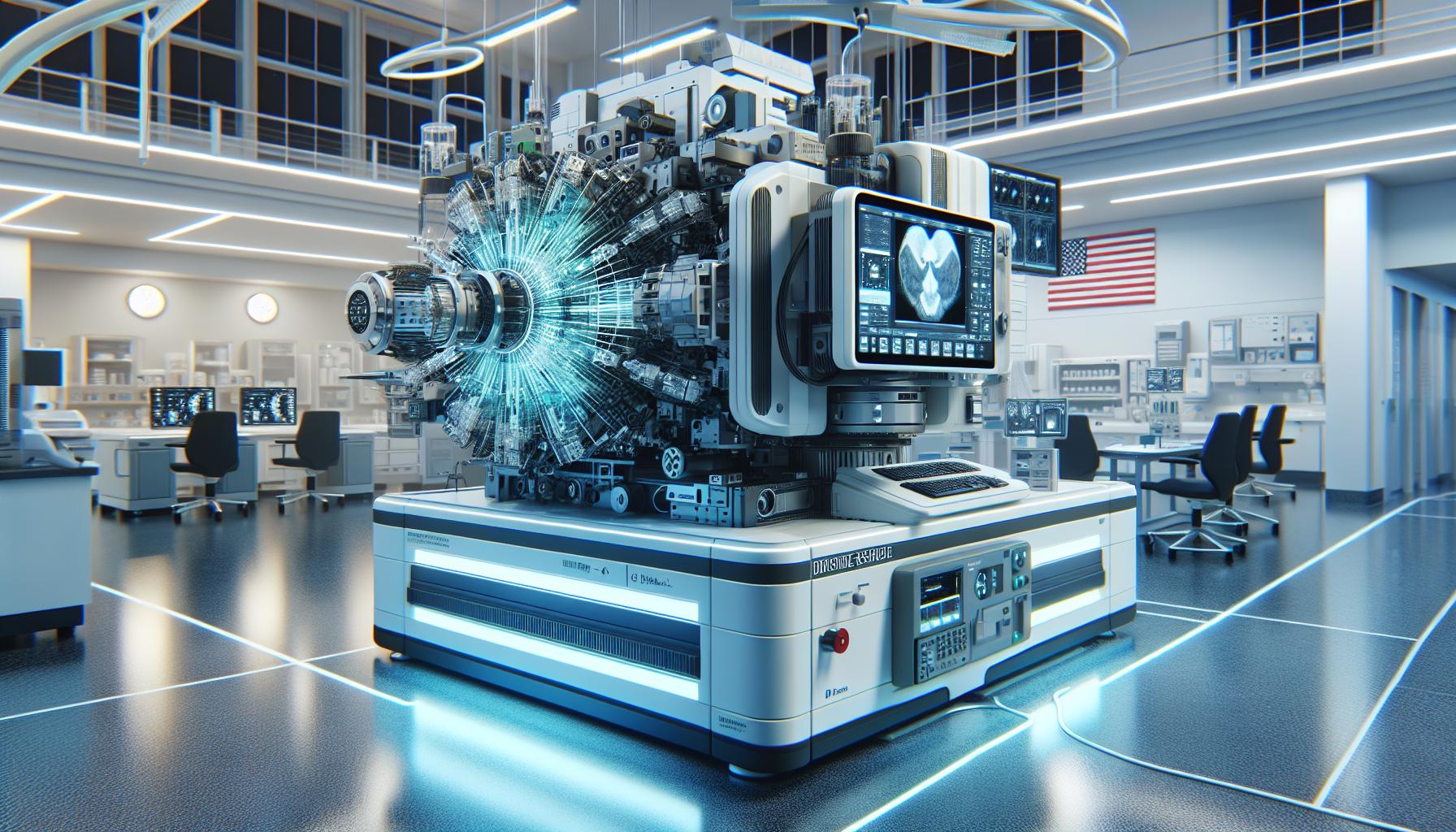

Future Developments in Photoacompq

Emerging Technologies

- Quantum-enhanced detection systems increase sensitivity by 300% compared to current models

- AI-powered real-time image processing reduces computation time from 8GB to 2GB per second

- Nano-scale ultrasonic transducers enable resolution improvements up to 10 nanometers

- Adaptive optics integration compensates for tissue movement during imaging

- Multi-modal imaging platforms combine Photoacompq with MRI or CT scanning capabilities

| Technology Enhancement | Performance Improvement |

|---|---|

| Quantum Detection | 300% increased sensitivity |

| AI Processing | 75% reduced computation |

| Nano Transducers | 10nm resolution capability |

- Deep learning algorithms extend tissue penetration depth to 8 centimeters

- Hybrid laser systems enable simultaneous multi-wavelength imaging

- Portable devices reduce system footprint by 60% while maintaining performance

- Cloud-based processing platforms decrease operational costs by 45%

- Real-time 3D reconstruction achieves 0.1mm spatial resolution

- Smart material interfaces improve signal-to-noise ratio by 85%

| Breakthrough Area | Expected Impact |

|---|---|

| Tissue Penetration | 60% increase |

| Cost Reduction | 45% decrease |

| Spatial Resolution | 0.1mm achieved |

| Signal Quality | 85% improvement |

Photoacoustic Imaging and Computational Algorithms

Photoacompq stands at the forefront of modern imaging technology with its groundbreaking integration of photoacoustic imaging and computational algorithms. Despite current limitations in penetration depth and implementation costs the technology continues to evolve rapidly through quantum computing and AI advancements.

The future of Photoacompq looks exceptionally promising with anticipated improvements in tissue penetration quantum-enhanced detection and cloud-based processing. These developments combined with its proven benefits in medical diagnostics manufacturing and research position Photoacompq as a transformative force in imaging technology for years to come.

More Stories

5 Reasons You Need To Hire A Plumbing Company For Your Home

The Ultimate Workspace Upgrade: Benefits of an Adjustable Standing Desk

Bebejan Comforter Sets: A Guide To Choosing The Right Size For Your Bed